Process

From 0 to 100% satisfaction

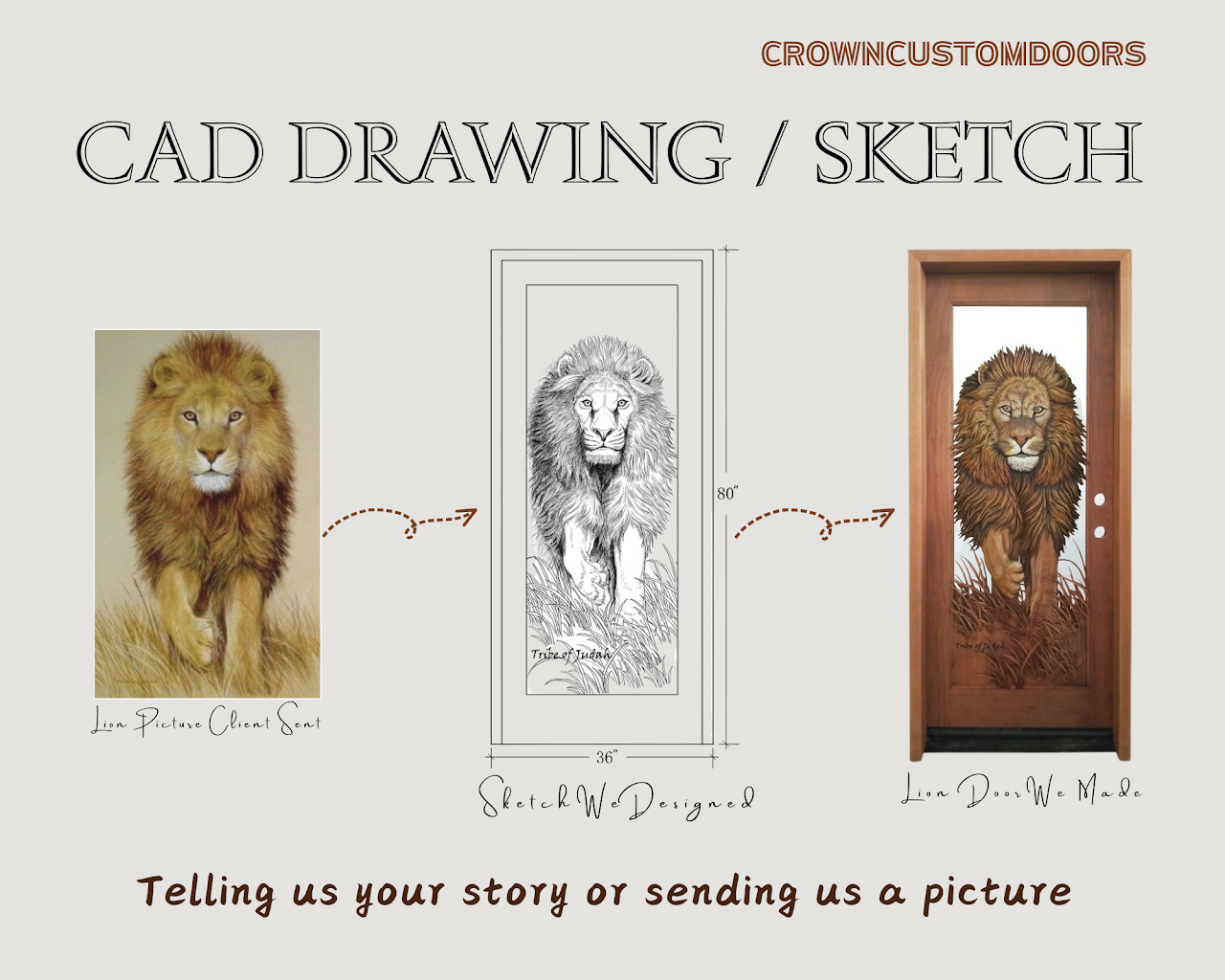

Shop Drawing

1st Step: Shop drawing/sketch Design

Shop drawings based on architectural renderings

Usually, clients be involved in designing their own works by telling us STORIES or sending us a picture. Just be bold, tell us your THOUGHTS, let yourself be involved to design your own door, we just help to bring your ideas to become alive.

Design a drawing/sketch of your door is FREE Of CHARGE.

Wooden Furniture

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis pulvinar

Custom Work

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis pulvinar

Exterior Furniture

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis pulvinar

Our Pricing

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- qui in ea voluptate velit esse

- vel illum qui dolorem eum

- fugiat quo voluptas nulla

Basic Plan

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

$34

/ Month

- nostrud exercitation ullamco

- laboris nisi ut aliquip ex ea

- sint occaecat cupidatat non

Premium Plan

Lorem ipsum dolor sit amet, consectetur adipiscing elit.

$74

/ Month

- nostrud exercitation ullamco

- laboris nisi ut aliquip ex ea

- sint occaecat cupidatat non

- deserunt mollit anim id est

Carpentry

2nd Step: Carpentry

Machining lumber to project specifications, hand hewn, pegged, doweled joined and mortise and tenon construction. Using a time-honored tradition, door frames, jambs, joinery tenon and mortise construction via custom build forms.

Upholstering Leathers

Elegant

CROWNCUSTOMDOORS makes beautiful, high-quality leather full of craftsmanship, conveys a sense of luxury and refinement.

Luxurious

Focus on intricate tufting suggests creating opulent and comfortable pieces of art.

Skilled

Emphasize the expertise and attention to detail involved in the upholstery work.

Inviting

Evokes a sense of warmth and comfort, making you want to sink into the upholstered furniture.

Timeless

Classic style and use of high-quality materials suggest that the pieces will retain their beauty and value for years to come.

Carving

3rd Step: Carving

For those carved wood doors, carving is the 3rd step, carvings are all done by hand, to your exact specifications, leaving no detail overlooked which offer endless possibilities.

Relief Carving:

This is the primary technique used for these doors. Relief carving involves carving a design into a flat surface, leaving the design raised from the background.

The carvers used chisels and gouges of various sizes to create the intricate details and textures in the wood.

2. Deep Relief Carving:

Some of the designs, like the “Eagle Mating” door, show deep relief carving where the figures are sculpted in high relief, almost three-dimensional.

This technique requires careful planning and execution to ensure the stability and balance of the carved elements.

3. Intaglio Carving:

While less prominent in these doors, intaglio carving might have been used for certain details or accents.

This technique involves carving into the wood to create lines and textures that appear recessed or engraved.

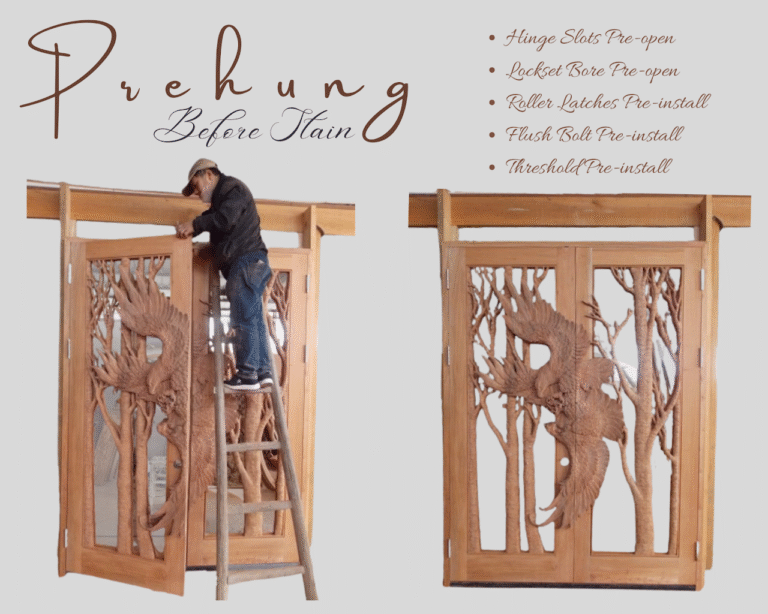

Prehung

4th Step: Pre-hung

Pre-hung in a structural jamb with side light frames, matched to door size.

These jambs are ideal for conventional wood frame homes, masonry construction, as well as for log homes or post and beam construction. This is because all CROWNCUSTOMDOORS jambs are structurally built, and therefore allow the logs or beams to shrink and contract while the jamb stays straight and plumb. You may order structural jambs any depth to accommodate your log size. Hardware like hinges, door shoe sweep, threshold, roller latches will be pre-installed during this step.

Pre-Hung Doors include:

- Rabbeted Stop - All pre-hung door jambs include a rabbeted stop. This 1CM thick door stop is a permanent part of the structural jamb. It is created by cutting a dado cut into the jamb, to receive and seal the door in a closed position. This method insures a perfect seal every time. Unlike tacked on door stops that usually shift over time from the pounding force of opening and closing, this stop will remain tight and plum to your door.

- Weather Package - The weather package is included in all pre-hung doors. Every door ordered pre-hung in a jamb is fitted with high density weather seals installed in the 1CM thick rabbeted stop. These double sized weather seals ensure the best protection from the elements. Also, all side light and transom glass is installed and fitted with stops and sealed for long term comfort as well as the very best energy conservation.

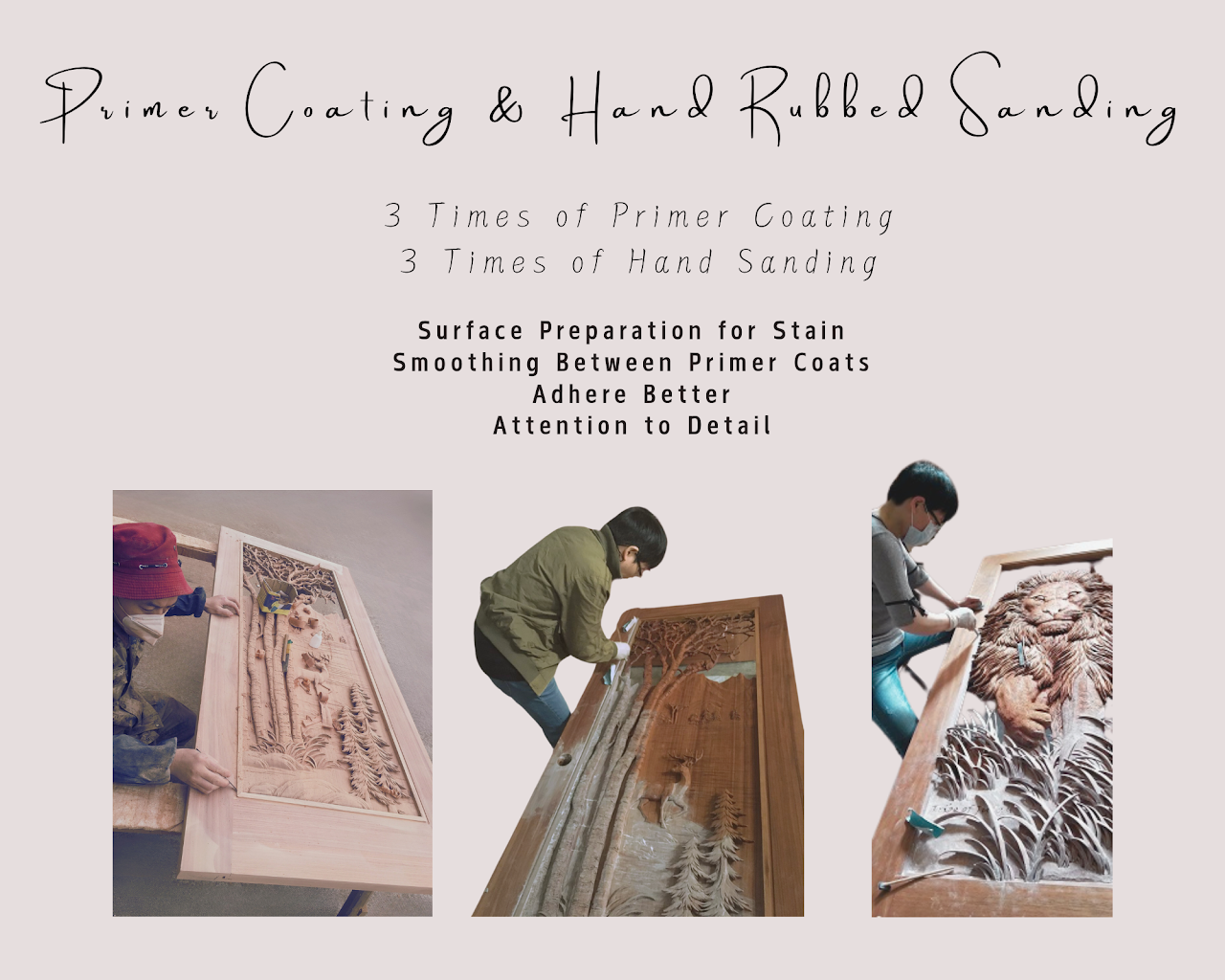

Primer Coating & Sanding

5th Step: Primer Coating & Hand Sanding

All finishes on our custom fine art doors, gates, furniture, and furnishings are processed and hand applied by our master finishers and to world class fine art antiquity standards.

Every door you order from CROWNCUSTOMDOORS includes your choice of hand-rubbed fine furniture finishes and/or textures.

Hand Rubbed Furniture Finish – Our finish process includes five to ten coats of hand rubbed, furniture quality, clear oils or water based, non-toxic lacquers. It is applied, cured, rubbed and re-applied depending upon whether your order is Limited Edition or old growth Original work. Every surface of our custom doors are fine finished including the undersides and hidden areas. These doors are built to investment, family heirloom, quality and are finished to be virtually maintenance free and will stand the test of time. Most of our finishes are water based and earth friendly. You may order any single color or texture finish at no extra charge.

We are an authority on fine art, solid wood furniture and wrought iron hardware finishes. Over the years we have developed and redeveloped many of the finish processes that have become the accepted standard finishes for fine art furniture manufacturers and artisans around the world. We have pioneered new finishes and processes with the focus, for several decades, on developing water base lacquers due to the environmental requirements of our planet, as well as the health and safety of our consumers and employees. Today we continue to improve on old tried and tested finishes as well as continuing our effort to go green.

Stain & Finish

6th Step: Stain & Finish

CROWNCUSTOMDOORS features a state-of-the-art finishing department that offers hundreds of finish options. A large percent of our custom wood door orders are finished in ten or more – process, hand rubbed, fumed in, clear lacquers and many other finish products. Customers may select items with a matte, satin, semi-gloss, wax, french polish or many exterior or interior finishes, or conversely order barn wood appearances, raised grain, weathered, old Spanish, or saw tooth textured finishes. All our exclusive finishes are environmentally safe, non-toxic, and are applied by hand then rubbed to perfection the “Old Fashioned Way”.

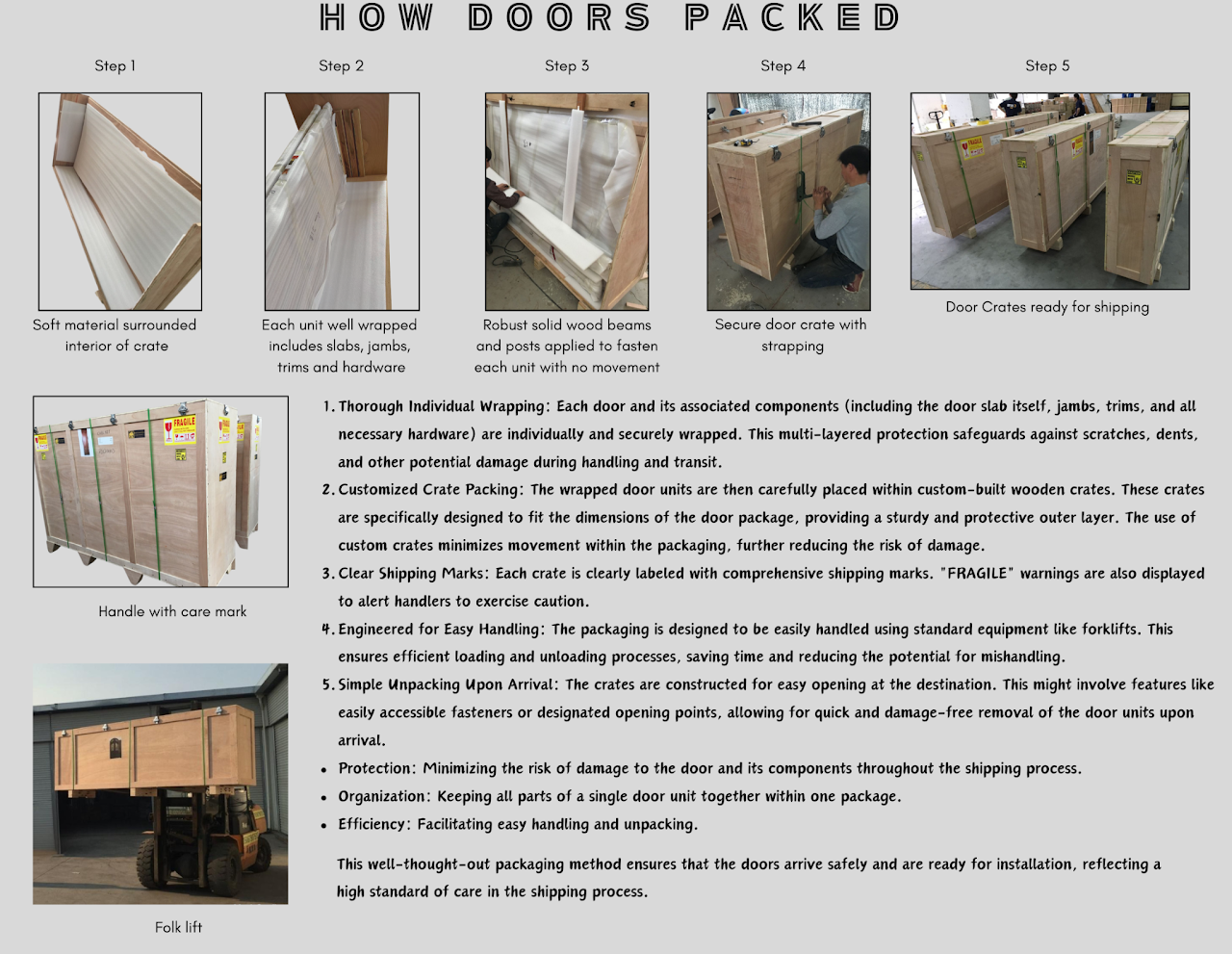

Crate Package & Shipping

7th Step as Last Step: Crack Packing & Shipping

Sturdy Crate for worldwide shipping CROWNCUSTOMDOORS assures each of custom wood door shipped out of factory directly to client’s home. We call it ‘DOOR to DOOR‘ term. Clients have nothing to do until doors arrival.

Crafting an Original

Custom wood doors require the inventive mind of a designer and the soul of a craftsman. We are proud to develop original solutions that challenge “it can’t be done” thinking, while hand crafting each unit to perfection. What sets us apart is that we work very closely with homeowners, architects, designers, and builders on every step of the process. We take the time to listen to what our clients want and build it right, every time. CrownCustomDoors are meticulously crafted in our headquarters, combining old-world artistry with progressive and innovative processes that defy conventional limits of function, performance and aesthetics.

Each door is made from carefully selected woods and FSC® certified as required — Mahogany, Teak, Alaskan Yellow Cedar and White Oak among others — species renowned for their beauty, strength and permanence. Each step in the making of a door builds on the previous, reaching a level of refinement found only in fine heirloom cabinetry. The result leaves a distinct, sensual feeling in hand that simply cannot be replicated in an off-the shelf-solution. From initial concept to post-installation support, our team brings the same precision, knowledge, and innovative attitude to every step of the process.

Tree-Themed Doors

Steve's Home Theater

Kimber's Home Theater

Allen's Home Theater